How Technology is Changing the Construction Industry: A Look at Innovations and Trends

Humans have been building structures for thousands of years. And for many centuries, we have historically relied on manual labor and traditional techniques for construction. However, technological advancements have significantly transformed the construction industry in the last few decades.

The building sector is going through a massive technology-driven shift that is streamlining procedures, increasing productivity and improving safety. This transformation started with adopting computers as creative tools and incorporating robotics and the Internet of Things (IoT).

This article will examine how technology transforms the construction industry and helps it prepare for a digital future while highlighting some of the most significant innovations and trends reshaping how we build.

Robotics and Automation

Thanks to innovative workflows that link design processes with mechanized manufacturing, the construction industry is seeing a boom in automation, which presents a new potential to incorporate industrial robotics.

Although it requires a sizable initial investment, automation ultimately saves time, money and resources while enhancing quality assurance and control and improving working conditions for employees.

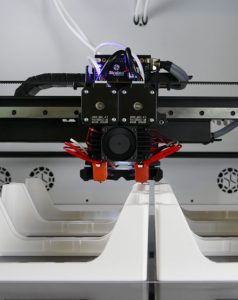

Robotic systems can perform repetitive tasks such as bricklaying, concrete pouring, and 3D printing of entire structures. These developments speed up construction, improve accuracy and lower labor expenses. Drones are also used for site surveys, progress monitoring and inspections, delivering real-time data and enhancing safety on construction sites.

The Internet of Things (IoT)

The IoT is changing how people relate to their physical environment in cities, homes and workplaces. For example, smart construction sites are now possible thanks to sensor technology and the Internet of Things (IoT).

Today, construction businesses can gather real-time data on various characteristics, including temperature, humidity, vibration and structural integrity, by embedding sensors in construction equipment, machinery and structures.

This data makes predictive maintenance possible by improving equipment performance and decreasing downtime. IoT devices also increase safety by tracking employee locations and sending out alerts in case of emergencies.

This solution brings to any construction project:

- Ease of visualization of the state of the infrastructure

- Sustainable securitization of investments

- Testing of construction quality

- Cost reduction in repairs

- Reduction of inspection costs

- Control of inspection intervals

- Minimize mean-time-to-repair (MTTR)

Building Information Modeling (BIM)

Building information modeling (BIM), which enables the generation and management of digital representations of buildings and infrastructure, has been the cornerstone of the architectural, engineering and construction (AEC) sector’s digital transformation.

BIM has completely changed the construction business by facilitating the seamless collaboration of architects, engineers and contractors on a common platform, minimizing frequent mistakes and conflicts during the building process.

BIM combines numerous elements, including facilities management, 3D modeling and cost forecasting to give a thorough project lifecycle perspective. With the help of this technology, construction businesses can improve communication, minimize rework and improve accuracy and productivity.

3D Printing

The construction process is changing thanks to additive manufacturing, also known as 3D printing. When combined with virtual and augmented reality, 3D printing is a helpful technology to present models and generate new materials specially designed for a situation or scenario within a construction project. As a result, 3D printing allows companies to enhance building safety and design and build intricate architectural designs faster and more precisely.

3D printers can also stack materials to create parts and even whole structures using digital models as a guide. Additive manufacturing cuts down on material waste while simultaneously speeding up construction. Thus, new opportunities for environmentally friendly building and cost-effective housing are made possible by 3D printing.

Augmented Reality (AR) and Virtual Reality (VR)

Augmented and virtual reality are transforming architecture, construction and design processes by generating different practices, for example:

- They allow clients to visualize the project’s final result before completion

- Through augmented reality (AR), on-site personnel can overlay digital information onto the physical environment with real-time guidance to speed up decision-making

- It enables a preview of the different finishing options available

- It also allows one to “visit” a construction site through a simulator without going physically

These technologies can also facilitate the work of engineers since:

- Virtual simulators provide information on the construction landscape in real-time

- They help predict which machinery and materials are necessary for the project

- Recommended equipment can be planned and purchased for potential risk areas where workers must interact

A Whole New Future for Construction

The way that projects are created, planned and carried out is changing due to innovations and trends driven by technology. Processes are becoming more streamlined, efficiency is rising, and safety is improving thanks to these developments.

Adopting these technologies will give construction companies a competitive edge regarding cost savings, project timeliness and quality to pave the way for a more efficient, sustainable and profitable industry.

Interested in receiving more great construction news, research and content from NCCER? Click here to join our mailing list!